Every detail counts in agriculture. That’s why we at SHW have developed products specifically designed to make your daily work easier and increase your productivity.

Enjoy the peace of mind that comes with our 3-year warranty on our tines in conjunction with the matching SHW bushing.

A promise that helps you plan and manage for the long term.

In the rare event of a failure, we will provide a replacement within 72 hours. This fast replacement service minimizes downtime and keeps you up and running.

Our products are your backup for demanding jobs. The outstanding stability of our tools means less worry about breakdowns and more focus on what really matters – your work.

SHW is your partner in working more efficiently. Our tools are designed to work and just keep on working, giving you significant productivity gains. Less time spent on repairs and maintenance means more time for your farming projects.

A carefully selected range of tools to meet your every need – from tillage to harvesting. Each of our products is a building block for your success, helping you work more efficiently and profitably.

| Double-T-Profile | Ø 35 – 42mm Length: 500 to 1400mm | Low weight: Handling: vertical lifting and lowering | |

| Star Profile | Ø 35 -44mm Length: from 500 to 1500mm. | Our allrounder Stable – forces can be absorbed from all sides | |

| Square Profile | Ø 35 – 55mm Length: 500 to 1500mm. | Combines all capabilities. Due to large cross section high forces can be absorbed | |

| Round Profile | Ø 25 – 55mm Length: 400 to 1550mm. | Strongest version High weight – working tool becomes heavier |

We will be happy to advise you and respond to your individual wishes – more information is available on request.

Load test (load capacity test on request)

Metric thread with recommended tightening torque

M | Nm |

M20x1,5 | 450 |

M22x1,5 | 500 |

M24x1,5 | 550 |

M27x1,5 | 600 |

M28x1,5 | 700 |

M30x2,0 | 700 |

M33x2,0 | 1000 |

Only tested products receive the double quality seal (SHW logo with crown, Made in Germany and production date).

Our products are “Made in Germany”

A nut is included with all tines

Are you looking for an individual solution or do you have any questions?

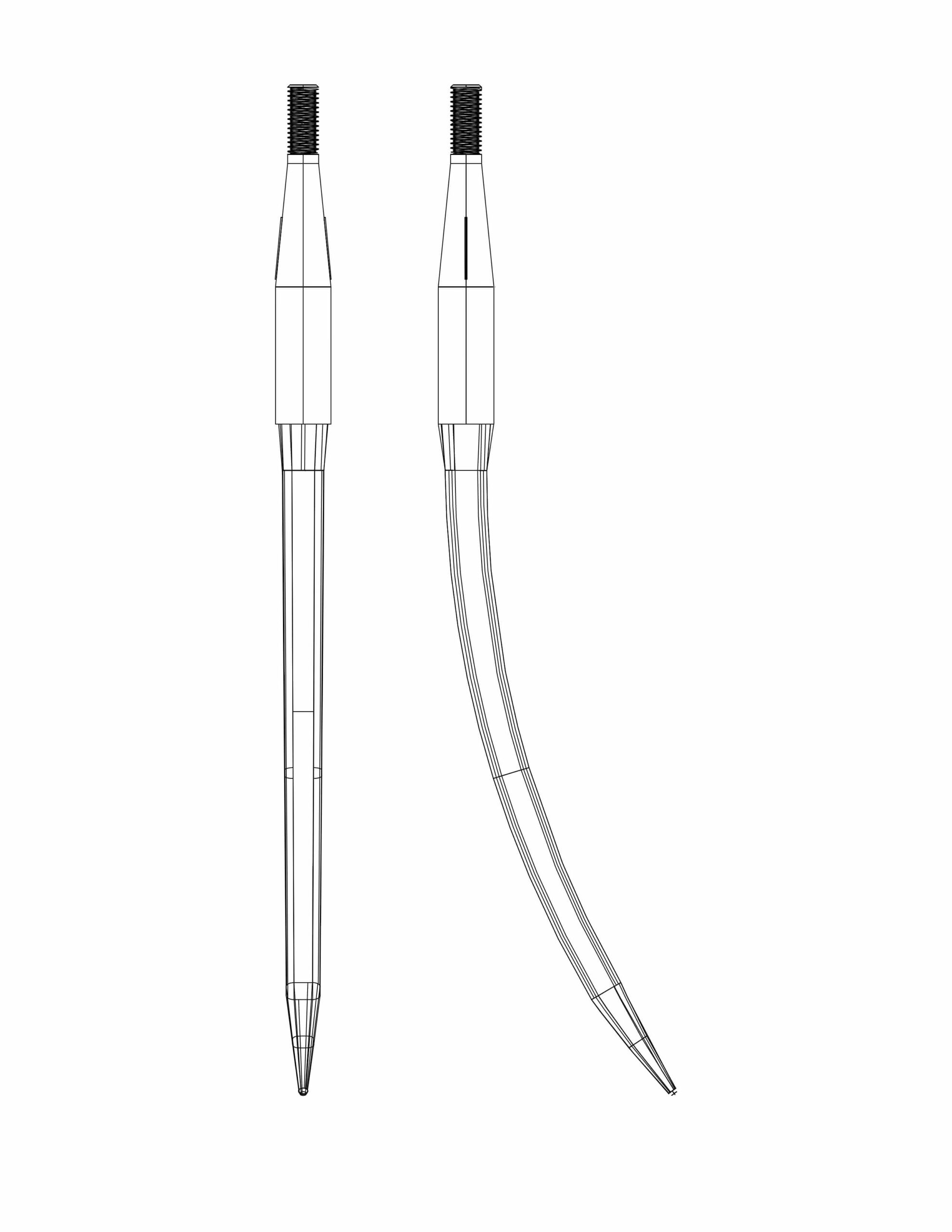

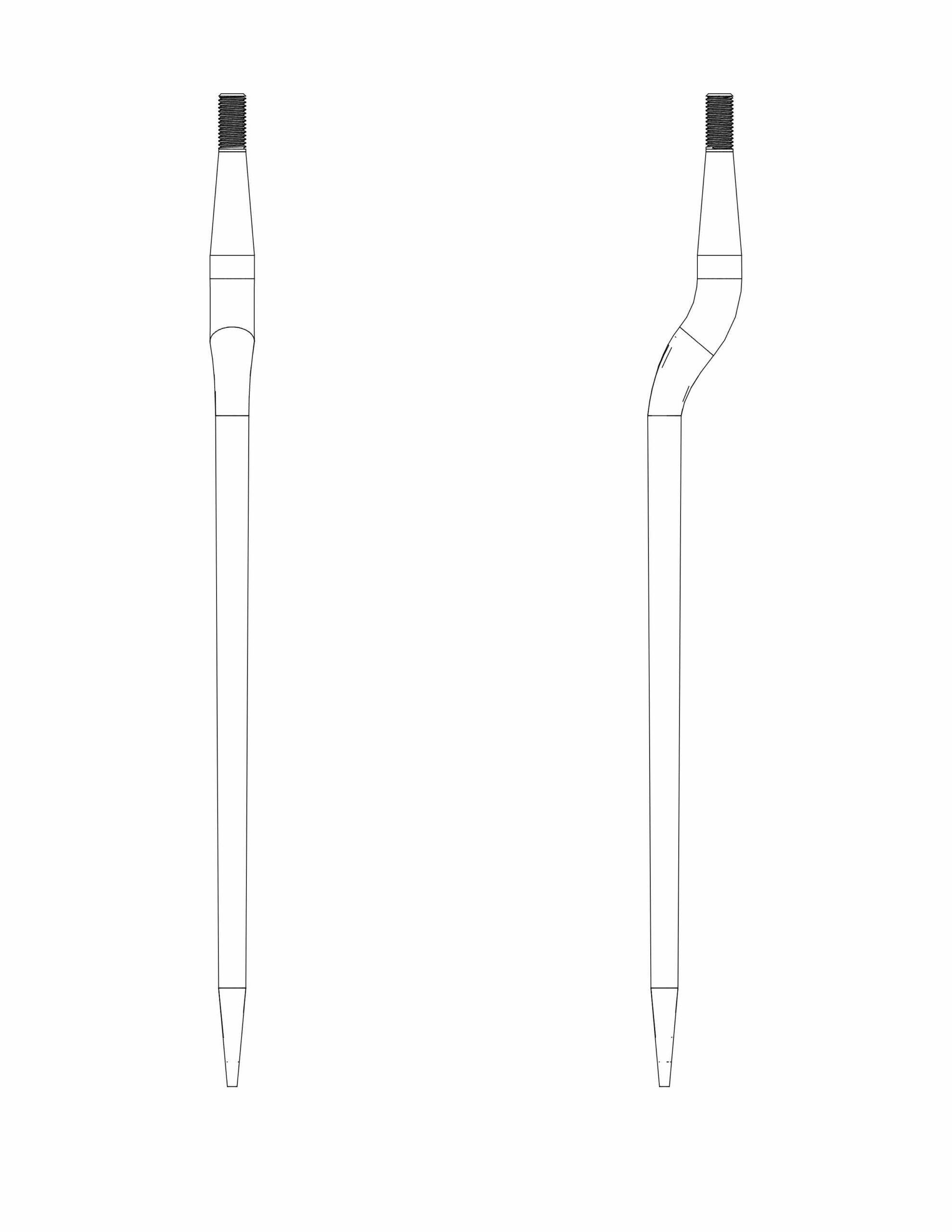

Explanation of interaction: sleeve – cone / prong

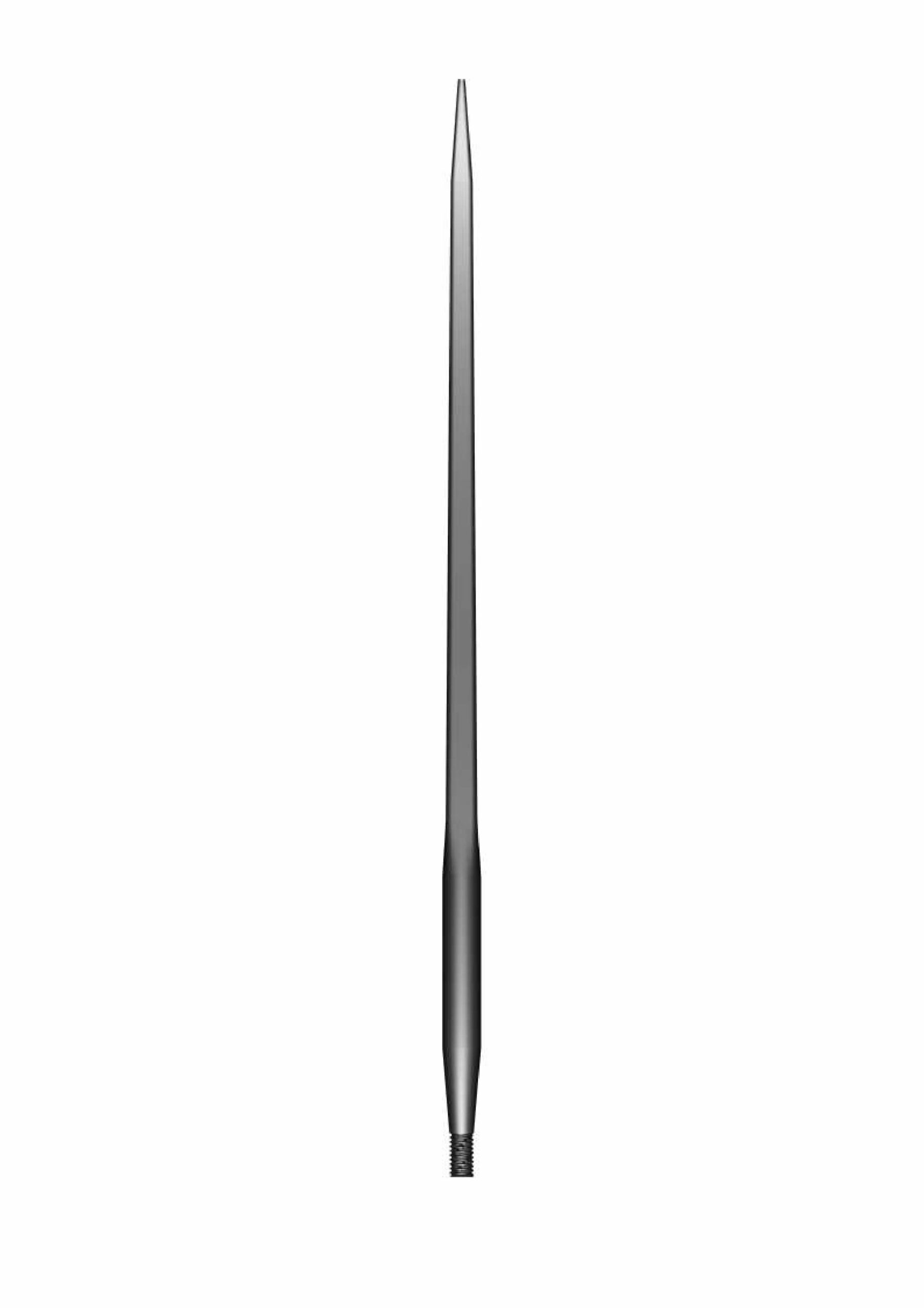

Fig.: Fit of a tine Ø 36mm with cone K001 in an original SHW bushing VB001

The article name of a tine is: 4077/1250, K013, M28

We know that your success in farming depends on reliable tools. That’s why we at SHW Landtechnik are committed to providing you with products that not only make your job easier, but also contribute to your bottom line. With SHW at your side, you have more than just tools – you have a partner who understands what you need to succeed.

Take the next step to more efficient farming with SHW Landtechnik.

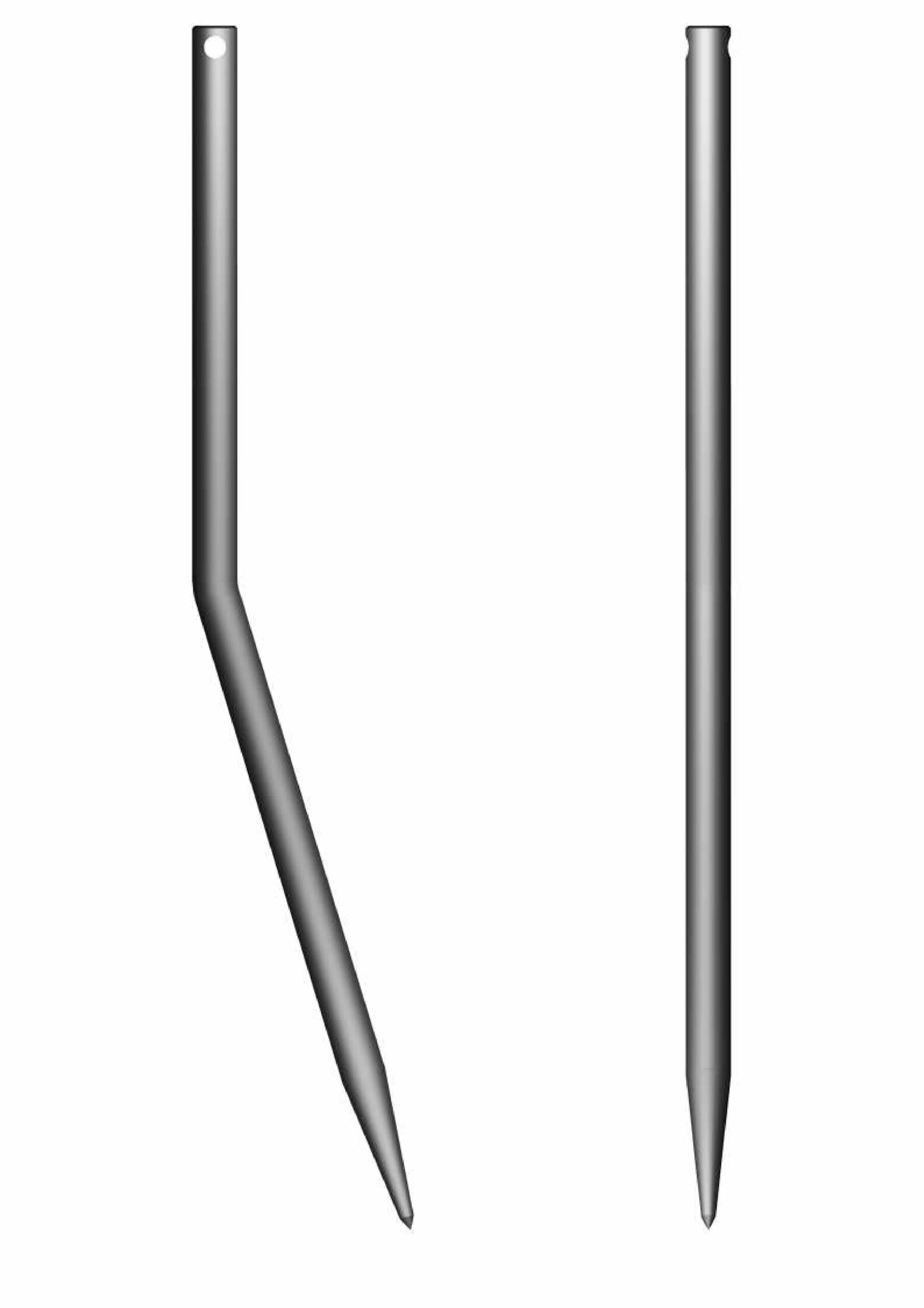

According to this principle, SHW has been manufacturing high-quality wear parts for the agricultural machinery industry for decades, with a focus on front loader tines and tools for soil cultivation. We use only profile-rolled spring steel with the tightest tolerances for this purpose. In combination with the hardening process, this gives our tines the highest load-bearing capacity and flexibility. All tines are subject to a 100% inspection at the end of the manufacturing process.

For optimum use of the SHW tines, we strongly recommend the use of an original SHW sleeve. Only this combination guarantees a perfect, snug fit. All SHW sleeves and also the cone of the tine are manufactured on modern CNC machines.

SHW now has more than 200 different cones and bushes in its product range. With our processing machines, customer-specific wishes can thus also be realised easily and quickly.

The core of our front loader tine production is the fully automatic forging plant, a combination of stretching robot and stretching roller. Another handling robot connects the subsequent processing stations.

In this way, we ensure reproducibility and dimensional accuracy in front loader tine production that is unparalleled on the market.

Do you have questions about SHW agricultural technology?

Benefit from Jannik Dieterle’s know-how when it comes to SHW agricultural technology products. He will be pleased if you contact him and will be happy to help you.

If you have any questions or need help, please contact our team.

SHW SCHMIEDETECHNIK GmbH & CO. KG

Wilhelm-Heusel-Strasse 18

72270 Baiersbronn – Friedrichstal

©2025 SHW SCHMIEDETECHNIK GmbH & CO. KG, All Rights Reserved